I purchased a dental chair and equipment from Oral Health Cart. The quality is excellent, and the installation was smooth. Their support service is prompt and professional. Affordable pricing and great experience overall. Highly recommend their services.

Discover Top-Rated Dentists Near You for Exceptional Oral Care

Money back

10 Days Money Back Guarantee

Zero shipping Charges

Zero Shipping charges on all orders above 1500

Special Deals

Special Deals on All OHC Products

Featured Products

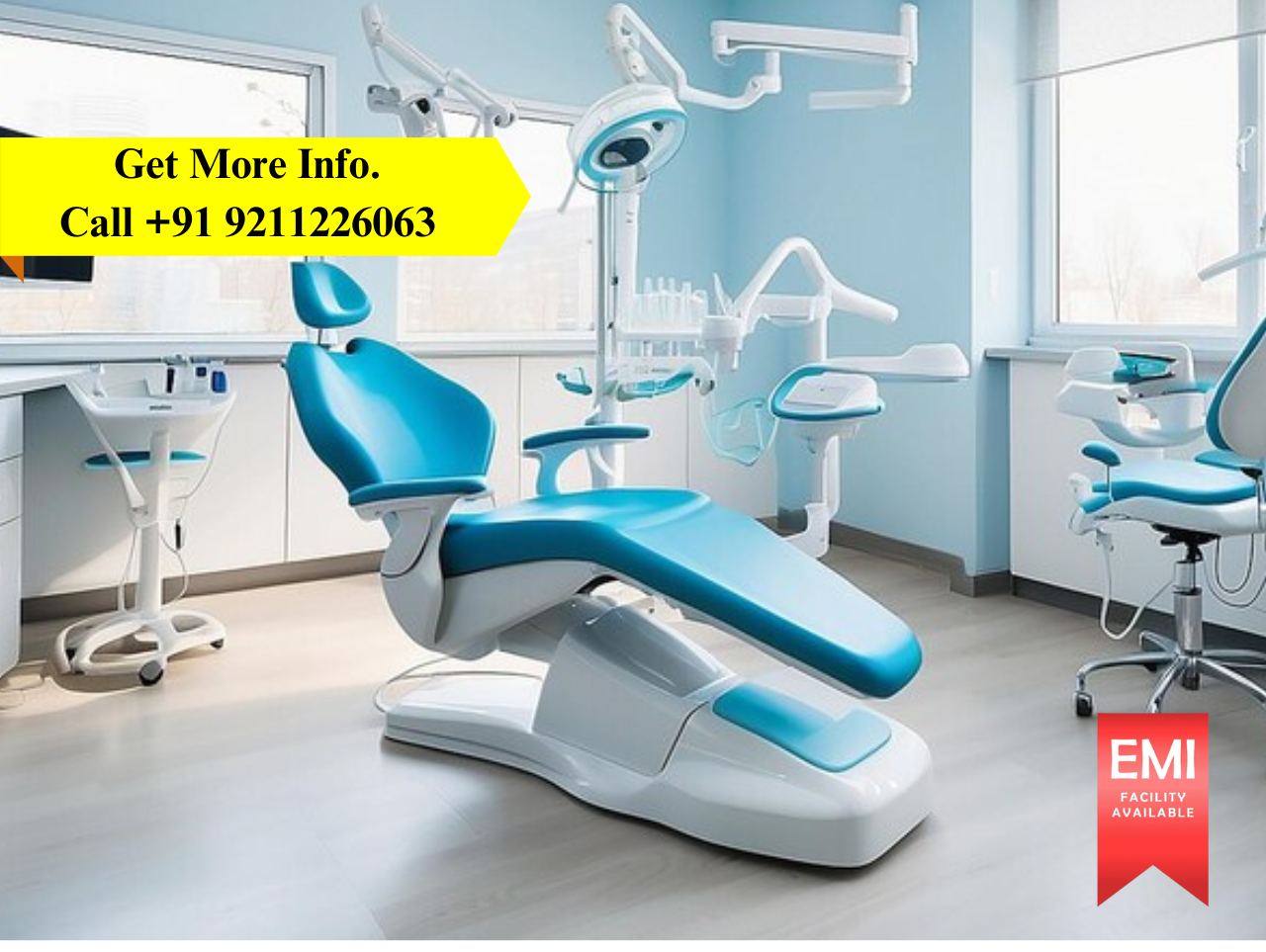

New Dental Clinic Setup - Economy (Free Pan India Delivery and Installation)

New Dental Clinic Setup - Advanced (Free Pan India Delivery and Installation)

New Dental Clinic Setup - Premium (Free Pan India Delivery and Installation)

New Dental Clinic Setup - Regular (Free Pan India Delivery and Installation)

SDI Luna Kit - Nano Hybrid Composite With Bonding Agent (Pack of 5 ) 5 syringe

High Demand Products

What Dentists Say About Us

.jpeg)

"Hello I'm Dr. Renu Tanwar .I am practicing in Noida(Uttar Pradesh).I have purchased my complete Dental setup from OralHealthCart.com

It was a great experience with Team OHC. I bought my dental chair for my clinic along with Compressor, X-ray and RVG. Highly recommended if anyone of you is searching for any such supplier for Dental Clinic.

Thank you and highly recommend it to all."

"Hello I"m Dr. Komal Gahalyan .I am practicing in Ballabhgarh (Haryana).I have purchased my complete Dental setup from OralHealthCart.com

Very good chair...working very fine...staff is very polite.. Quick service... Highly recommended!!

Thank you and highly recommend it to all."

"Hello I'm Dr. Alzaid Khan .I am practicing in Maharashtra (Thane).I have purchased my complete Dental setup from OralHealthCart.com

I purchased a dental chair and equipment from Oral Health Cart. The quality is excellent, and the installation was smooth. Their support service is prompt and professional. Affordable pricing and great experience overall. Highly recommend their services.

"Hello I"m Dr.Devanshi Sharma .I am practicing in Behror (Rajasthan).I have purchased my complete Dental setup from OralHealthCart.com

.jpeg)

"Hello I"m Dr.Kanak Sen .I am practicing in Tinsukia,(Assam).I have purchased my complete Dental setup from OralHealthCart.com

Very good chair...working very fine...staff is very polite.. Quick service... Highly recommended!!

Thank you and highly recommend it to all."

Oralhealthcart Products

Oralhealthcart Products

.jpeg)

.jpeg)